KUSTERMANN (RINA): “THE CHOICE OF MATERIALS IS CRUCIAL FOR ON-BOARD COMFORT”

Shipyards invest a lot of resources to mitigate noise and vibrations, but the result is not always satisfactory and technicians often realize the problems when construction is already at an advanced stage and the solutions become complex and expensive. SUPER YACHT 24 spoke to Lorenzo Kustermann, a mechanical engineer who graduated from the Polytechnic of Milan with a specialization from the University of Southern California in Los Angeles and who has been the soul of Rina’s noise & vibration department for three years: “Our work includes the noise and vibration parts, both with the subcategories of development of calculations for prediction and measurements on board. In some cases the customer detects a problem and asks us for a solution to resolve it, in others we work right from the initial stages of the project. And then there is all the certification work, which concerns the additional Comfort Class COMF(Y) for yachts (which corresponds to the COMF -NOISE and COMF-VIB of ships)”.

Consulting and certification: how are the activities divided?

“Classification is Rina’s historical activity. Consulting is a more recent area and through Rina Consulting – the branch of the company that deals with engineering consulting – we provide complete and customized solutions to ensure comfort on board yachts”.

What are the main sources of vibration and noise?

“Engines, ventilation and air conditioning systems, propellers. Engine vibrations are transmitted through the keelsons, the transverse and longitudinal reinforcement structures and the bulkhead of the engine room which, being made of metal, transfers them well. Ventilation and air conditioning systems (HVAC), in particular the air handling units (ATU), can be very noisy. The propellers, as they rotate, pressurize the water and hit it against the stern vault, transmitting vibrations to the entire hull”.

What are the challenges in predicting and mitigating noise and vibration?

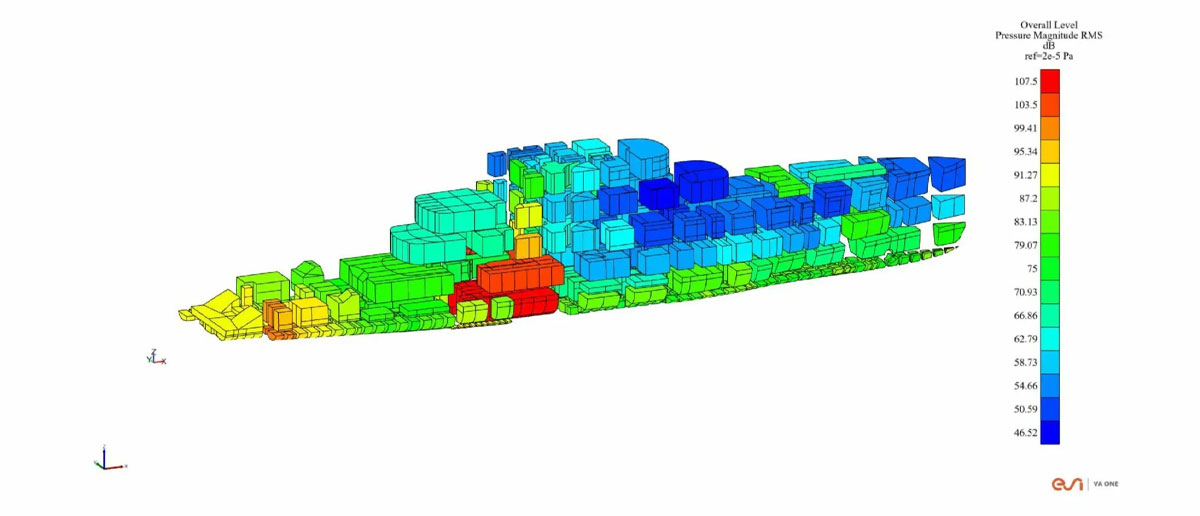

“One of the biggest challenges is the complexity of the forcing stresses, such as engine noise, its vibrations transmitted through the structures and the Uta. For this reason, at Rina we use cutting-edge commercial software such as VA One by Esi for statistical energy analysis (SEA) that allows us to model the yacht in cavities and simulate the energy transmission between them. Unlike others, we pride ourselves on being among the few to use such sophisticated calculation models”.

How does the Statistical Energy Analysis (SEA) process work and how do you validate the accuracy of the forecasts?

“Sea models the yacht in cavities, i.e. volumes, taking into account the different stresses that can be vibration or pressure, and therefore noise. For example, we insert the sound pressure level of the engine room into the model and the software calculates how the energy is transmitted to the adjacent cavities. We validate the accuracy by comparing the results of the simulations with the measurements then taken on board: the predictions are very accurate, with deviations of about 1 decibel”.

What is the role of Fem (Finite element method) modeling?

“FEM modeling allows us to predict the vibration behavior of structures and evaluate the effectiveness of countermeasures. The modeling results can be visualized through graphs and color maps that highlight the areas with the highest vibration levels and quickly identify the weak points of the structure and intervene in a targeted way. We have been using these models for over 20 years and we reach a very important level of detail”.

What is the importance of consultancy in the design phase compared to simple certification, and what are the risks of neglecting a preventive analysis?

“Consulting is essential. If we come on board for certification and find incorrect values due to incorrect design choices, we may not be able to issue the certification or issue it with a low comfort rating. This can have a negative impact on the customer and the sale of the yacht. Consulting allows us to identify and resolve problems during the design phase, avoiding costly modifications later on”.

What are the most important challenges at this stage?

“Managing the complexity of the data needed for simulations, which often arrive late in the construction process. This requires close collaboration with shipyards to obtain detailed information on material thickness, structural reinforcements and many other characteristics of the yacht.”

How does the choice of materials and construction techniques affect comfort?

“The choice of materials is crucial and a substantial part of the comfort comes from the type and thickness of the glass. A 12 mm monolithic glass dampens the noise a lot, but an 8 mm double glass with internal polymer dampens it more effectively. The characteristics of the reinforcing beams and bridges also influence the dissipation of energy. All these factors must be part of the Sea analyses: the more accurate you are in providing data, the more accurate the results will be. In summary: bad input, bad results”.

Do you also analyze external noise?

“Yachts are increasingly performing and there is a continuous search for comfort by owners and shipyards. The VA One software is also useful for analyzing noise on external decks and creating very accurate forecasts to take the necessary countermeasures and understand if and where to add insulating or damping materials such as rock wool, glass wool or rubber. Furthermore, thanks to another software, Nova, we can simulate noise on board and evaluate its quality perceived by the customer. These techniques are pushed to extreme levels in the automotive world; in yachting we are still in the early stages and, still, we are among the few to exploit them”.

New technologies coming?

“We are using an acoustic camera, which allows us to precisely locate the sources of noise, and we use software that simulates the sound experience, allowing us to evaluate the quality of the sound and identify the most annoying frequencies. Another frontier is the motion camera, which visually amplifies the vibrations of the panels, helping us to identify the most critical areas”.

What instruments do you use to measure noise and vibration on board?

“We use Sinus Soundbook and Noisepad, tools that provide great versatility by allowing us to measure sounds and vibrations at the same time. Another interesting measurement is the noise reduction index, which evaluates the ability of an environment to reduce the noise coming from another adjacent, noisier environment. In the latter we place an instrument that emits, for example, a noise of 100 decibels and in the cabin to be evaluated we measure how much that noise has been reduced. Similarly, with a special hammer we evaluate the ability of a bridge or a bulkhead to dampen vibrations, hitting one area and evaluating how much the vibration amplitude decreases in the other”.

What kind of reports do you provide after the analysis?

“Rina provides detailed reports that include vibration and noise levels measured in different areas of the ship, specifying the measurement zones and conditions, and include maps showing their distribution in different areas of the ship in colour scales from blue to red”.

What is the trade-off between maximum vibration and noise reduction and the cost to achieve it?

“It always depends on the severity of the problem. If all the guests on board are seasick, there is no maximum price because you risk not selling the yacht. Each shipyard makes its own assessments on whether to intervene or not. In the design phase everything is still easily solvable, after that it becomes more complex”.

Is there a yacht whose achievements you are particularly proud of?

“The last three Palumbo Superyachts models we have worked on are excellent, both in terms of vibration and noise. We are proud of them because we have worked with them from design to launch.”

Source: Superyacht24